2015.06.10

Properties based on flow analysis

Properties based on flow analysis Resin joints made of PEEK(Provided by: AOI Co., Ltd.)

Resin joints made of PEEK(Provided by: AOI Co., Ltd.) Resin joints made of PEEK(Provided by: AOI Co., Ltd.)

Resin joints made of PEEK(Provided by: AOI Co., Ltd.) Resin joints made of PEEK(Provided by: AOI Co., Ltd.)

Resin joints made of PEEK(Provided by: AOI Co., Ltd.)Daicel-Evonik’s PEEK Resin VESTAKEEP

Adopted in Element Parts for High-functional Piping Joints

Daicel-Evonik Ltd. (Head Office: Shinjuku-ku, Tokyo; President: Andre Noppe) is pleased to announce that its PEEK resin VESTAKEEP has been adopted by AOI Co., Ltd. (Head Office: Gotemba-shi, Shizuoka; President: Katsumi Onoda) for use in their resin joints “PS-fit”.

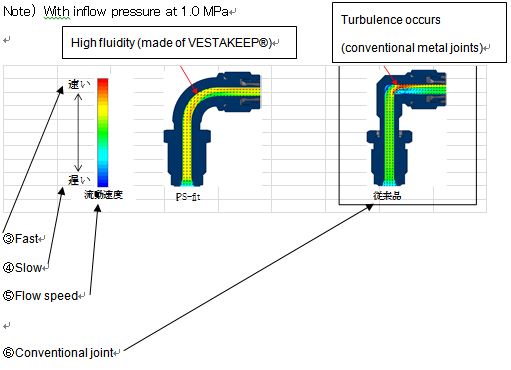

Compared to conventional metal joints, PEEK resin joints have reduced their weight by approx. 80%, while achieving smoothness of flow inside the piping by using a special injection molding method, thereby preventing turbulence of fluid that flows inside, and exercising excellent fluidity without causing pools inside the joint. PEEK resin joints have also tested improved operating efficiency and high productivity through repeated use.

PEEK resin VESTAKEEP is also used as a base polymer, thereby achieving heat resistance that tolerates an environment of up to 150℃. In addition to this high heat resistance, VESTAKEEP enables use in an environment where chemical resistance, rust-proof quality and/or electrical insulation are required. This is why this PEEK resin can be used for broad purposes, including semiconductor production equipment, food and beverage machinery, automobile coating process, and medical device facility.

At Daicel-Evonik we aim to raise our reliability even further, and will continue to provide tailored technical support to customers.